Tailwheel cables

Moderators: GAHorn, Karl Towle, Bruce Fenstermacher

-

MontanaBird

- Posts: 38

- Joined: Mon May 02, 2005 6:19 pm

Tailwheel cables

Dear fellow birdmen/women

I have a Scott 3200 on my 170B. I noticed today, well actually quite a while ago, that the rudder cables extending to the tailwheel have some slack in them. I elevated the tail off the ground somewhat to inspect the cables in the 'flight' position, which of course tightens them to some extent.

Yet, I remain unsure at to the proper tension in the cables, and how this should be checked.

Any thoughts appreciated. Thnx

I have a Scott 3200 on my 170B. I noticed today, well actually quite a while ago, that the rudder cables extending to the tailwheel have some slack in them. I elevated the tail off the ground somewhat to inspect the cables in the 'flight' position, which of course tightens them to some extent.

Yet, I remain unsure at to the proper tension in the cables, and how this should be checked.

Any thoughts appreciated. Thnx

- Bruce Fenstermacher

- Posts: 10422

- Joined: Tue Apr 23, 2002 11:24 am

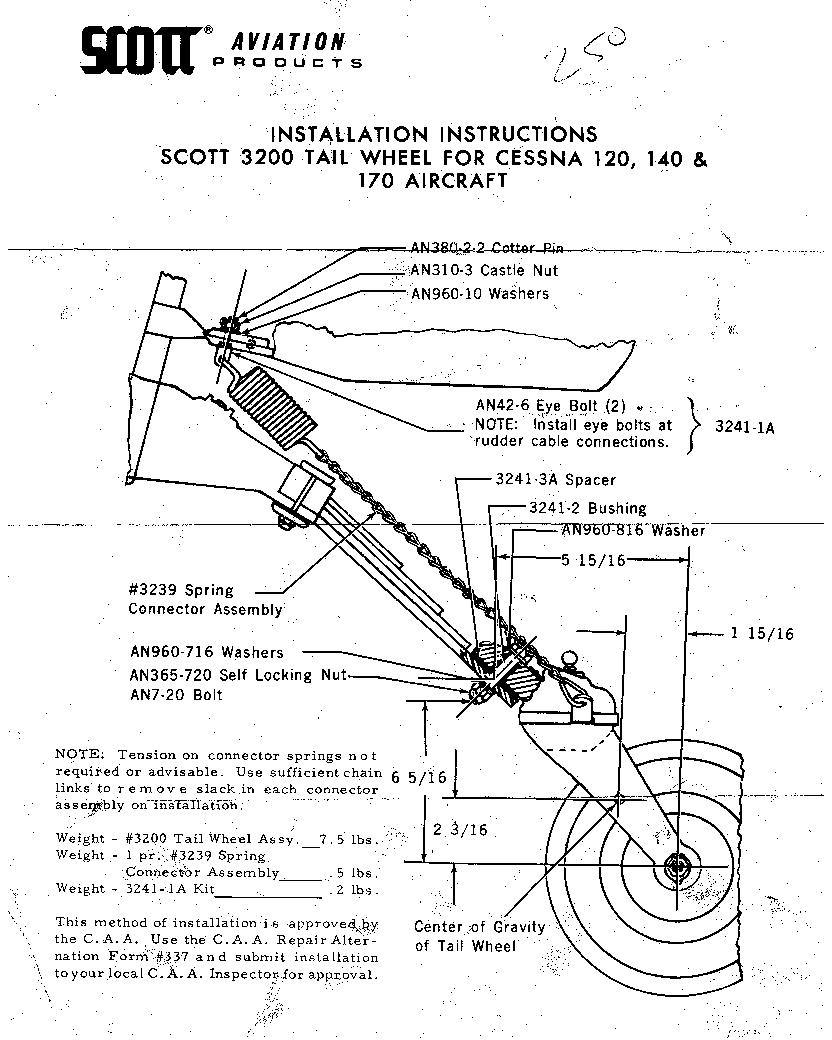

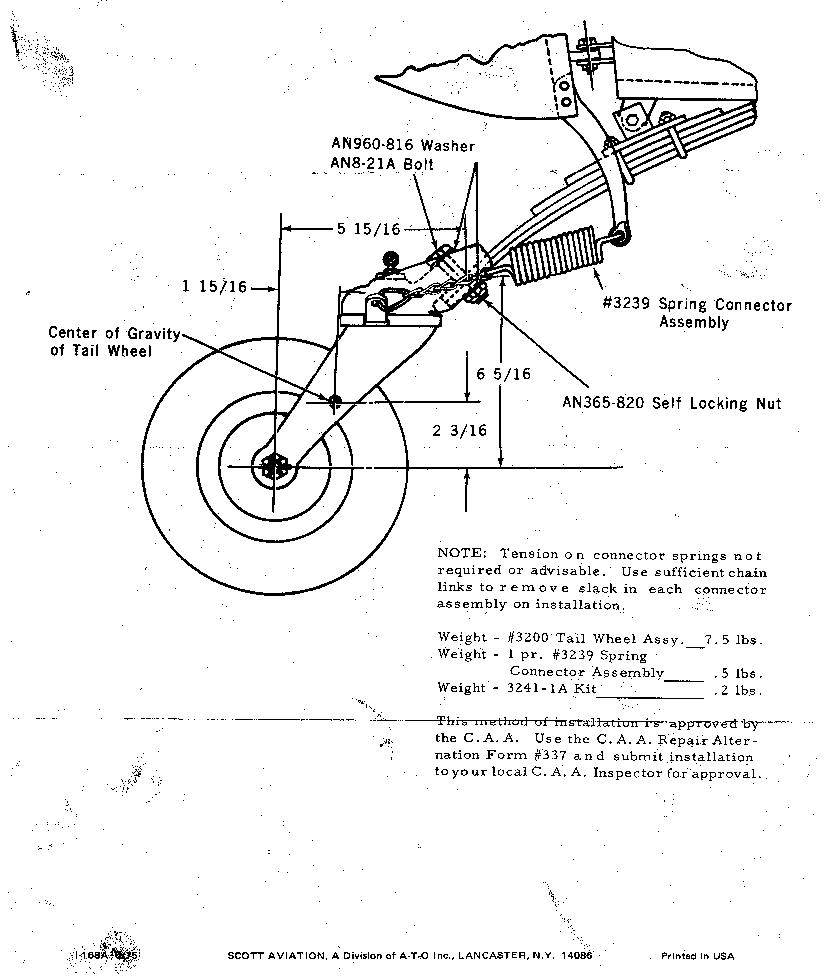

With the tail wheel of the ground and the airplane supported under the fuselage so the spring and wheel hang free, the chain should have no slack. Not tight, not loose. Both sides should be the same.

You can adjust this by removing links till the chain is a bit snug. Then very gently slightly squeeze several links to elongate them till the chain is just right.

You can adjust this by removing links till the chain is a bit snug. Then very gently slightly squeeze several links to elongate them till the chain is just right.

CAUTION - My forum posts may be worth what you paid for them!

Bruce Fenstermacher, Past President, TIC170A

Email: brucefenster at gmail.com

Bruce Fenstermacher, Past President, TIC170A

Email: brucefenster at gmail.com

- GAHorn

- Posts: 21295

- Joined: Fri Apr 12, 2002 8:45 pm

A difference of opinion might exist on this.... I believe the airplane should be loaded to 2,000 lbs and the steering chains should be taut while the airplane is in a 3-point stance. (The tension springs allow for the tailwheel to descend slightly in flight.)

'53 B-model N146YS SN:25713

50th Anniversary of Flight Model. Winner-Best Original 170B, 100th Anniversary of Flight Convention.

An originality nut (mostly) for the right reasons.

50th Anniversary of Flight Model. Winner-Best Original 170B, 100th Anniversary of Flight Convention.

An originality nut (mostly) for the right reasons.

- Bruce Fenstermacher

- Posts: 10422

- Joined: Tue Apr 23, 2002 11:24 am

George if the chains are snug on the ground with lbs then any other time except when heavier there is a greater load on the cables and tail wheel. But of course there would be no slop in the linkage.

Been a long time since I've fooled with my tail wheel trying to improve the steering but seem to remember it made very little difference if I had the slop that is associated with the tension method I described or the one you described. I tried both.

Since I saw no benefit in steering I choose to go with the method that gave the least tension. If you can live with the extra tension and side load on the tail wheel almost all the time then OK, but it bugs me.

As always individual results may vary. Of the three 170s I've flown the most mine is the worst for tail wheel ground handling with the best being a 180 conversion which is the heaviest on the tail wheel. Go figure.

Been a long time since I've fooled with my tail wheel trying to improve the steering but seem to remember it made very little difference if I had the slop that is associated with the tension method I described or the one you described. I tried both.

Since I saw no benefit in steering I choose to go with the method that gave the least tension. If you can live with the extra tension and side load on the tail wheel almost all the time then OK, but it bugs me.

As always individual results may vary. Of the three 170s I've flown the most mine is the worst for tail wheel ground handling with the best being a 180 conversion which is the heaviest on the tail wheel. Go figure.

CAUTION - My forum posts may be worth what you paid for them!

Bruce Fenstermacher, Past President, TIC170A

Email: brucefenster at gmail.com

Bruce Fenstermacher, Past President, TIC170A

Email: brucefenster at gmail.com

- GAHorn

- Posts: 21295

- Joined: Fri Apr 12, 2002 8:45 pm

Bruce, while some owner/operators may modify their aircraft to suit their own ideas, I believe most prefer to know and comply with the mfr's original design. And unless a standardized installation method is used, then each and every owner will have to re-invent the tailwheel.

Cessna specifies that the airplane's landing gear adjustments be made at 2,000 lbs aircraft weight. (CG within the envelope for flight.) Scott installation instructions specify that "sufficient chain links be removed to remove slack" in the steering chains.

Any other methods carry the liklihood of masking additional malfunctions within the tailwheel steering system. (I doubt anyone in the engineering/design departments will agree that smashing steering-chain links to adjust tension is a good idea. I believe the correct method is to allow the springs to do their intended jobs of taking up slack....from a beginning point of no-slack while on the ground. Those springs allow for ordinary tailwheel leaf-spring movements when airborne.) IMHO

Cessna specifies that the airplane's landing gear adjustments be made at 2,000 lbs aircraft weight. (CG within the envelope for flight.) Scott installation instructions specify that "sufficient chain links be removed to remove slack" in the steering chains.

Any other methods carry the liklihood of masking additional malfunctions within the tailwheel steering system. (I doubt anyone in the engineering/design departments will agree that smashing steering-chain links to adjust tension is a good idea. I believe the correct method is to allow the springs to do their intended jobs of taking up slack....from a beginning point of no-slack while on the ground. Those springs allow for ordinary tailwheel leaf-spring movements when airborne.) IMHO

'53 B-model N146YS SN:25713

50th Anniversary of Flight Model. Winner-Best Original 170B, 100th Anniversary of Flight Convention.

An originality nut (mostly) for the right reasons.

50th Anniversary of Flight Model. Winner-Best Original 170B, 100th Anniversary of Flight Convention.

An originality nut (mostly) for the right reasons.

-

N2865C

- Posts: 507

- Joined: Sat Oct 18, 2003 9:07 pm

The Scott installation instructions also say that tension on the chains is not necessary or desirable. I also use N9149A's method of gently squeezing a few links to get the chains just right...... No slack and no tension.gahorn wrote: Scott installation instructions specify that "sufficient chain links be removed to remove slack" in the steering chains

John

N2865C

"The only stupid question is one that wasn't asked"

N2865C

"The only stupid question is one that wasn't asked"

- GAHorn

- Posts: 21295

- Joined: Fri Apr 12, 2002 8:45 pm

I believe that remark in the Scott installation instructions is intended to discourage actual extension/stretching of the tension springs while on the ground....it is not in order to allow slack in the chain....as proved in the follow up instruction I quoted. No slack is to exist. (Think about this: If the chains are slack...then what purpose do they serve? It'd be better to simply have a full-castering tailwheel.)

There is no reason for the existence of the tension springs except to allow the leafspring movement and allow for rare overstresses such as when full-swivel is initiated. If the tailwheel remained fixed, relative to the fuselage and rudder, then no tension springs would be necessary. Further, the tension springs, if extended...would defeat the purpose of their counterpart. The comment you quote regarding no stretching of the springs being desired ...is intended to prevent the defeat of the steering system. This is because any stretched tension-spring would have to allow it's counterpart to nearly collapse before any steering took place! This would prevent effectiveness of the steering sytem from the outset!

The tension springs are intended to be fully taut...along with the steering chains...in order to place a steering input to the tailwheel...on the ground. (Obviously, it makes no difference while airborne.) The designed tension of those springs is all the tension the tailwheel should ever receive in order to encourage it to steer while taxying. Any stresses over-and-above that ordinary steering effort ...is to be releived by those springs in order to avoid damage. That is their purpose.

To further illustrate the point.... if the same logic (suggesting slackened chains) were applied to other tension springs in the rudder system....(Imagine for a moment the tension springs forward of the rudder pedals that keep the rudder cables taut).... then one would have to move the rudder pedals some distance before the rudder actually moved at all, due to slop. The relative wind would keep the rudder streamlined, rather than the rudder doing any steering whatsoever.

There is no reason for the existence of the tension springs except to allow the leafspring movement and allow for rare overstresses such as when full-swivel is initiated. If the tailwheel remained fixed, relative to the fuselage and rudder, then no tension springs would be necessary. Further, the tension springs, if extended...would defeat the purpose of their counterpart. The comment you quote regarding no stretching of the springs being desired ...is intended to prevent the defeat of the steering system. This is because any stretched tension-spring would have to allow it's counterpart to nearly collapse before any steering took place! This would prevent effectiveness of the steering sytem from the outset!

The tension springs are intended to be fully taut...along with the steering chains...in order to place a steering input to the tailwheel...on the ground. (Obviously, it makes no difference while airborne.) The designed tension of those springs is all the tension the tailwheel should ever receive in order to encourage it to steer while taxying. Any stresses over-and-above that ordinary steering effort ...is to be releived by those springs in order to avoid damage. That is their purpose.

To further illustrate the point.... if the same logic (suggesting slackened chains) were applied to other tension springs in the rudder system....(Imagine for a moment the tension springs forward of the rudder pedals that keep the rudder cables taut).... then one would have to move the rudder pedals some distance before the rudder actually moved at all, due to slop. The relative wind would keep the rudder streamlined, rather than the rudder doing any steering whatsoever.

'53 B-model N146YS SN:25713

50th Anniversary of Flight Model. Winner-Best Original 170B, 100th Anniversary of Flight Convention.

An originality nut (mostly) for the right reasons.

50th Anniversary of Flight Model. Winner-Best Original 170B, 100th Anniversary of Flight Convention.

An originality nut (mostly) for the right reasons.

- johneeb

- Posts: 1543

- Joined: Thu Jun 26, 2003 2:44 am

Re: Tailwheel cables

All of this dicussion about chains nothing about adjusting the cables, ala the later B models. A problem I wish I was faced with.MontanaBird wrote:Dear fellow birdmen/women

I have a Scott 3200 on my 170B. I noticed today, well actually quite a while ago, that the rudder CABLES extending to the tailwheel have some slack in them. I elevated the tail off the ground somewhat to inspect the cables in the 'flight' position, which of course tightens them to some extent.

Yet, I remain unsure at to the proper tension in the cables, and how this should be checked.

Any thoughts appreciated. Thnx

John E. Barrett

aka. Johneb

Sent from my "Cray Super Computer"

aka. Johneb

Sent from my "Cray Super Computer"

- GAHorn

- Posts: 21295

- Joined: Fri Apr 12, 2002 8:45 pm

It's the same discussion. The length of the chain is adjusted to take up the slack. (While on the ground.)

The only major difference between the two systems is that the later system suffers from failures within the fuselage at the bulkheads due to excessive rudder-circuit stresses which can pull the pulley-brackets and tear them from the bulkheads. It also complicates rudder-pedal feedback to the cockpit. (The later system, originally intended as a refinement, has no practical advantage, but can be an unnecessary complication, in my opinion.) KISS

The only major difference between the two systems is that the later system suffers from failures within the fuselage at the bulkheads due to excessive rudder-circuit stresses which can pull the pulley-brackets and tear them from the bulkheads. It also complicates rudder-pedal feedback to the cockpit. (The later system, originally intended as a refinement, has no practical advantage, but can be an unnecessary complication, in my opinion.) KISS

'53 B-model N146YS SN:25713

50th Anniversary of Flight Model. Winner-Best Original 170B, 100th Anniversary of Flight Convention.

An originality nut (mostly) for the right reasons.

50th Anniversary of Flight Model. Winner-Best Original 170B, 100th Anniversary of Flight Convention.

An originality nut (mostly) for the right reasons.

- Bruce Fenstermacher

- Posts: 10422

- Joined: Tue Apr 23, 2002 11:24 am

George I didn't say smash the steering-chain link, that would obviously be unauthorized. I was speaking of so slight of an "adjustment" over many links that it would not be detectable and not be obviously unauthorized.gahorn wrote: (I doubt anyone in the engineering/design departments will agree that smashing steering-chain links to adjust tension is a good idea.

CAUTION - My forum posts may be worth what you paid for them!

Bruce Fenstermacher, Past President, TIC170A

Email: brucefenster at gmail.com

Bruce Fenstermacher, Past President, TIC170A

Email: brucefenster at gmail.com

- GAHorn

- Posts: 21295

- Joined: Fri Apr 12, 2002 8:45 pm

- cessna170bdriver

- Posts: 4115

- Joined: Mon Apr 22, 2002 5:13 pm

Cessna® is a registered trademark of Textron Aviation, Inc. The International Cessna® 170 Association is an independent owners/operators association dedicated to C170 aircraft and early O-300-powered C172s. We are not affiliated with Cessna® or Textron Aviation, Inc. in any way.